Lamilux, a global market leader in composite material and a GRP specialist, has had a successful run in the Indian market. The company has put in tremendous effort to help customers in the bus and truck segments understand the benefits of GRP. The company has been aggressively focusing on helping the bus market upgrade by switching over to GRP solutions. Lamilux has identified India as one of its key focus markets for future growth.

In a conversation with BUS COACH INDIA magazine Mr. Rohan Bellikatti, Country Head-New Business Development (Middle East, India & Srilanka ) highlighted the Indian market scenario.

Q: Two year after the Covid-19 pandemic. What is the impact of this on the Bus Industry in general, Lamilux’ in particular?

Covid -19 had brought a standstill in the Bus Industry during the past 2 years. Starting this year the Bus Industry slowly started reviving and trying to regain its survival in the market. Yes, the Bus Industry suffered the maximum in the past 2 years and there were lot of struggles for the operators and also the Manufacturers who were forced to stop production and also operators who were unable to run their fleet due to strict covid norms. As there were no production of vehicles Lamilux also had to suffer as the manufacturers did.

Q: How has the Indian bus market responded to Lamilux’ products?

Lamilux is the Worlds No 1 GRP manufacturer because of the Innovation, Know-how and various solutions we bring to the table. Indian Bus Industry knows about our product and the conventional mind set which was earlier a few years back is slowly understanding and realizing the need for a change in approach. We have done more than 1000 + buses in India and till date we don’t have any complaints nor issues. Lamilux is working with all the OEM manufacturers both in Electric and Non electric segments. Apart from this few of the local bus body builders have started using our materials for the ease of application and high productivity, eliminating enormous manpower with reduced application time.

Mr. Rohan Bellikatti, Country Head-New Business Development (Middle East, India & Srilanka ), Mr. Manjul Bhatia, Country Head- Commercial Vehicle Division, during a Prawaas event organised in Hyderabad.

Q: Which industry sectors are your customers in, and which ones are growing fastest?

We are having customers in almost all the sectors namely Commercial vehicles (Reefer containers/Dry containers),Bus, Cold Rooms, Clean rooms, Construction, Caravans, Mobile Portable Offices, Shelter homes, Mobile hospitals, ISO tank containers and many more. Out of all the sectors commercial vehicles sector is rapidly growing. We now see lot of New 3 wheeler last mile delivery vehicles which are of EV and also diesel run 4 wheelers. We do have solutions for both EV vehicles and non EV vehicles.

Q: What are your most recent product innovations that you launched in Buses?

There are couple of products which we have launched in past few months. The Latest Launch which was done at Prawas 3.0 was the Gewebe S Special which is going to be the Next big thing for the Indian Bus Industry having the best of the parameters for the Roofing solution application. We do have the Gewebe SH 48% material which has been in this Industry from past years and been the go to product for all, apart from the Gewebe X-treme products for the buses whose manufacturers wish to have the corner profile also with Lamilux GRP without having any joints. We have also come up with few more composite floors which could be used as a flooring material which creates the Wow! effect when you step in the Bus.

Q: What are the major trends and developments affecting your category and your customers, and how are you responding?

Conventional approach and the way of thinking is one of the drawbacks for growth which many customers happen to have which is the reason why we are still called as a growing country! This is one of the reasons where we get resistance. The mind set of such customers is very difficult to change immediately but eventually they will realise and will change. I believe innovation and technology are something which one has to accept, adapt and make changes accordingly. There are only two ways which can happen “Either you be the driving force to make changes accepting the new developments or you will be driven to make changes forcefully to stay in the market” I would always prefer the first one for my customers and try educating them with the same. We at Lamilux believe that lot of the current generation know what we are trying to communicate in terms of Innovation, Technology and advancement in developments happening in so called Developed countries and trying to bridge the gap as soon as possible. Lamilux will always be the “One stop Solution provider “and be Innovating new products to cater to various segments of Market.

Q: What are the major challenges that you are facing in the market?

Mindset of people is the biggest challenge we face in the current market as willingness to change what is best is the last option where as it has to be one of the top 3 priorities the companies have. India is a price centric nation which we have to agree and its good in some aspects but puts technology at risks as Innovation comes with price and technology advancements. We believe that slowly people will realise what is the need for the hour and proactively act towards it to have a right balance of Price & Technology.

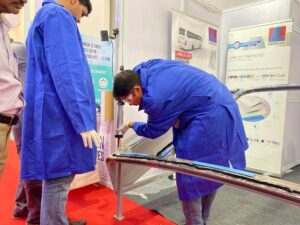

Lamilux India team showcasing a live demonstration at the stall at Prawaas

Q: Can you tell us about any areas where you’re currently making technical advances?

In the 1950s, Lamilux GRP corrugated sheet was installed on pergolas and terraces, later we produced GRP for rooflight domes, today we produce plastic panels for cladding in the vehicle industry – and tomorrow?

Experience always confirms to us that nothing is more enduring than change itself. That’s why we continue to develop our products – and look for new markets in which we can support with our expertise and GRP quality.

In order to transport the long-awaited COVID-19 vaccines in a safe, hygienic and refrigerated manner from production to the vaccination centres and store them properly there, special transport vehicles and containers are required. Impacts, impurities and, above all, temperature fluctuations must be avoided. Face sheets made of glass fibre-reinforced plastics (GRP) are assisting with this in the past 2 years.

The construction material LAMILUX X-treme GRP is used, among other things, as a face sheet for the internal and external walls of vaccine transport containers. This results in a surface that is extremely robust, even at temperatures of minus 80°C, easy to clean, corrosion-free and very light.

An additional option is the AntiBac function, which can be applied optionally to the glass fibre-reinforced plastic. Integrated nano-silver particles disinfect the surface, whereby multi-resistant germs die within just a few hours. The re-formation of critical germs is prevented.

Additional areas of application for LAMILUX X-treme AntiBac

This innovative composite material is already being used as a structural face sheet for refrigerated truck bodies, refrigerated warehouses and processing facilities in the food sector as well as in operating theatres in hospitals. This can reduce downtime throughout the food and cold chain.

We have the most X-treme composite on the market: The lightest and strongest tank cladding in the world thank to LAMILUX X-treme

Tank containers last for decades. During this time, it transports gases, oils, milk and other liquids – and an image. Its exterior shell is the operator’s business card. Cladding the container with LAMILUX X-treme glass-fiber reinforced plastic permanently protects the representative shell from UV, weather and mechanical effects.

LAMILUX X-treme is the spearhead of tank cladding materials. It is a fiber- reinforced composite material with the maximum possible content of reinforcement fibers in a highly elastic epoxy resin matrix. LAMILUX X- Treme designs save operators time and money. The shock-resistant material reduces maintenance and repair costs, thus reducing container downtime.